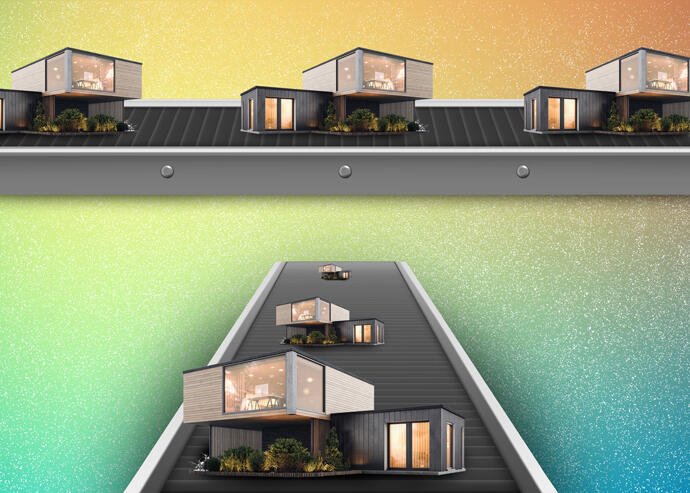

Quick turnaround times have luxury buyers considering modular as an alternative to traditional construction for grandiose homes. (iStock)

Modular construction, long associated with mobile homes, has gone high-end.

A market is developing for luxury modular homes as buyers look to take advantage of the quick turnarounds that factory manufacturing provides.

Anecdotes abound of the growing luxury market for modular homes. According to the Wall Street Journal, a seven-bedroom home with a pool, a pool house and other amenities designed by Resolution 4 Architecture sold in Bridgehampton, New York, last year for $4.7 million, its full asking price.

In general, modular construction appears to be ramping up nationwide. Seattle-based Method Homes reported a 50 percent increase in sales of prefab homes last year. The company built a new factory to keep up with demand.

The biggest advantage to building luxury modular is that turnaround times can be faster, as site preparation and foundation work can happen simultaneously to the factory manufacturing of a home, which is then delivered to the property and assembled, the publication reported.

Manufacturing companies are also able to automate much of the construction process. This allows them to keep costs down and avoid some of the problems in the construction industry, such as labor shortages.

Modular homes aren’t for everyone, though, especially clients who want the flexibility to change their minds mid-project. Many modular builders cannot alter design decisions after manufacturing begins. Additionally, not every site is good for a modular home, especially if transportation limits don’t allow the home to reach the property.

Modular construction has the backing of one of the world’s richest people, Warren Buffett. MiTek, owned by Buffett’s Berkshire Hathaway, recently launched a modular building venture. Another of the world’s wealthiest, Elon Musk, lives in a 375-square-foot modular unit.

[WSJ] — Holden Walter-Warner